The Lean Principle

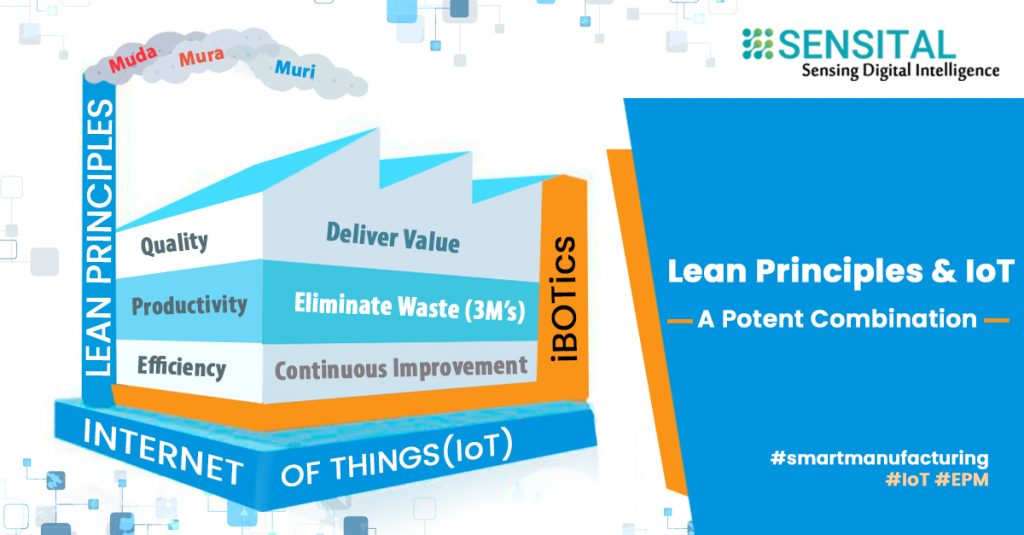

MUDA, MURA & MURI – These three Japanese terms (also called the Three Ms), used together by Toyota successfully in its Toyota Production System, collectively describe wasteful practices to be eliminated. MUDA is the actual wasteful activity that does not add any value in the value stream, MURA is a reference to any unevenness or inconsistency in the operations, and any overburdened situation is referred to as MURI. Going by these definitions, product defects or machine downtime are the classical examples of Muda, and overgrowing stockpile in a certain staging area may point to the existence of Mura. Similarly, excessive inventory in hand could be referred to as Muri. These 3 Ms have become the fundamentals of lean manufacturing, a practice that many companies are striving to adopt in their pursuit of increasing overall operational efficiencies.

The goal of the Lean Principle is to get the right things to the right place at the right time and in the right quantity, to achieve perfect workflow while minimizing waste & ensuring flexibility. However, fully identifying different types of waste & their root causes is an exhaustive exercise. It also requires complex correction techniques at different dimensions of people, processes & tools – typically implemented as a mix of multiple, disparate point solutions in the underlying IT & OT layers. Carefully selected IoT technology can be a key enabler in not only identifying the wastes in a timely manner but can also enable simpler solutions to eliminate them as a continuous cycle of improvements. IoT technology can help to monitor, raise alerts and provide automated controls, which can be leveraged to remove MUDA – Wasteful Activities, MURA – Unevenness or inconsistencies, and MURI – Overburden.

Intersection of IoT with Lean Principles

Manufacturing gained an efficiency boost when interconnected machines forming parts of SCADA or MES systems made it easier to apply lean principles. Given the downward pressure being applied to the manufacturing industry by the market forces, it has become imperative for the industry to inject a booster dose of efficiency improvement. IoT technology may provide such a booster, by allowing not only machines but also people, materials & processes to be monitored & controlled, thereby helping manufacturers to unveil the hidden efficiency improvement areas.

People, machines, materials, and processes can relay valuable information with the help of sensors and communicate it to a centralized system. Such timely alerts and actions help organizations to quickly identify the key performance indicators throughout the value stream that makes implementation of a complex system like JIT inventory management, a proven Lean model, a huge success. The collected data from these sensors, mapped collaboratively into different processes, enables picking up critical insights such as variances that help in reducing product defects (MUDA). Similarly, transportation waste can be reduced further and corrected with the help of continuous alerts-driven material movement tracking solutions. Such alert-based solutions can also be cross-functionally integrated to eliminate other more granular areas of waste e.g. waiting for related wastes at different stages of SCM such as reduced time at warehouse gate or quicker loading and unloading of goods into the transportation vehicles or moving the raw material in a more optimized manner.

However, it is important to note that simply correcting the MUDA with the help of condition monitoring and alerts may not help in preventing it from happening again. It is equally important to focus on the MURA and the MURI that usually drive different forms of wastes. An Enterprise Performance Management (EPM) system, built on a robust rules-based middleware like iBOTics, can help in addressing overburden and unevenness in the operations simply by collecting real-time

information from different parts of many ongoing processes to highlight the conditions resulting in overburden or inconsistencies. For example, IoT-enabled OEE tracking of different machines in conjunction with other production-based KPIs would significantly help in the prediction of MURA or MURI being created in the process. Machine sensor data can also help in identifying trends & correlations for predicting asset failures before it actually happens – thus avoiding unplanned downtimes (MUDA). Automated log management of critical events can also eliminate any documentation-related inaccuracies that may possibly impact the workflow & quality.

Driving Operational Efficiency with Business Intelligence

The lean philosophy strongly promotes Continuous Improvement methodology for long-term success. A rules-based IoT platform, such as iBOTics, makes this philosophy a reality. Such an EPM system is capable of managing collaborative processes across a mix of multiple machines, people & materials to monitor, control and raise automatic alerts across the value stream. Interoperable device connectivity, easily configurable rules, and out-of-the-box integration capabilities make it easy for such systems to break the siloes and manage all dimensions of lean principle-driven transformational implementations, like Value-Stream Mapping or JIT Inventory Management, which would otherwise remain out of reach for many manufacturers.

The right rules-based middleware technology should have the ability to model process maps to get real actionable insights from your operations as against just dumping time-series data of individual assets onto a central system offering lesser real-time control. These actionable insights can also be seamlessly and cross-functionally integrated with enterprise systems, with the additional ability of bi-directional information exchange between the IT and OT layers. Such a Digital EMP System will easily enable Continuous Improvement and help control costs, improve efficiencies, increase profitability, and most importantly, offer a better customer experience.